H-20 Load Ratings Explained

Editor’s Note (April 2025):

This post replaces an earlier version with updated and more accurate information about H-20 load ratings and how they relate to plastic and cast iron products. We’ve clarified key test methods and industry terminology to better support your product decisions.

What is an H-20 Load Rating? You may have seen this term used to describe cast iron products—or applied to plastic, composite, or concrete components. Depending on the source, it might refer to a product rated for 16,000 lbs, 20,000 lbs, or even 40,000 lbs. But what does "H-20" actually mean?

|

| Load Testing Setup |

Load Testing Setup

Let’s dig in with a little background. The term “H-20” comes from AASHTO, the American Association of State Highway and Transportation Officials. AASHTO maintains a document called the LRFD Bridge Design Specifications, the design standard by which bridges are designed and built in the United States. Within this document are various design scenarios, or loading cases, that define the weight a bridge and its components must safely support. One of these load cases is designated H-20. You may have heard of others—such as H-15, HS-20, or HS-25—but we’re focusing on H-20.

An H-20 loading refers to a two-axle truck with an axle load of 32,000 lbs, or 16,000 lbs per wheel. A safety factor of 2.5 is applied to this wheel loading, so the H-20 test load becomes 16,000 lbs × 2.5, or 40,000 lbs.

How does this design standard translate into a product rating? That’s where another AASHTO standard comes in—M-306.

The AASHTO M-306 Standard Specification

The AASHTO M-306 is the Standard Specification for Drainage, Sewer, Utility, and Related Castings. It applies to frames, lids, rings, gratings, and other castings that will be placed in roadways. The M-306 standard defines the materials, workmanship, and load capacity castings must meet to be safely installed in a roadway.

The AASHTO M-306 Standard applies to gray cast iron frames and covers that may be placed in traffic service and load bearing is a consideration.

It requires a safety factor of 2.5 x the H-20 loading, which equates to a 40,000 lb proof load (2.5 x 16,000 lbs).

A few key things to know about the M-306:

-

It applies only to castings and specifies that they must be made from Class 35 or 80-55-06 ductile iron. This means it does not apply to plastic, composite, or other non-iron products.

-

It defines how the rating must be verified, including how the load is applied and how the product is supported.

-

The H-20 proof load is 40,000 lbs.

-

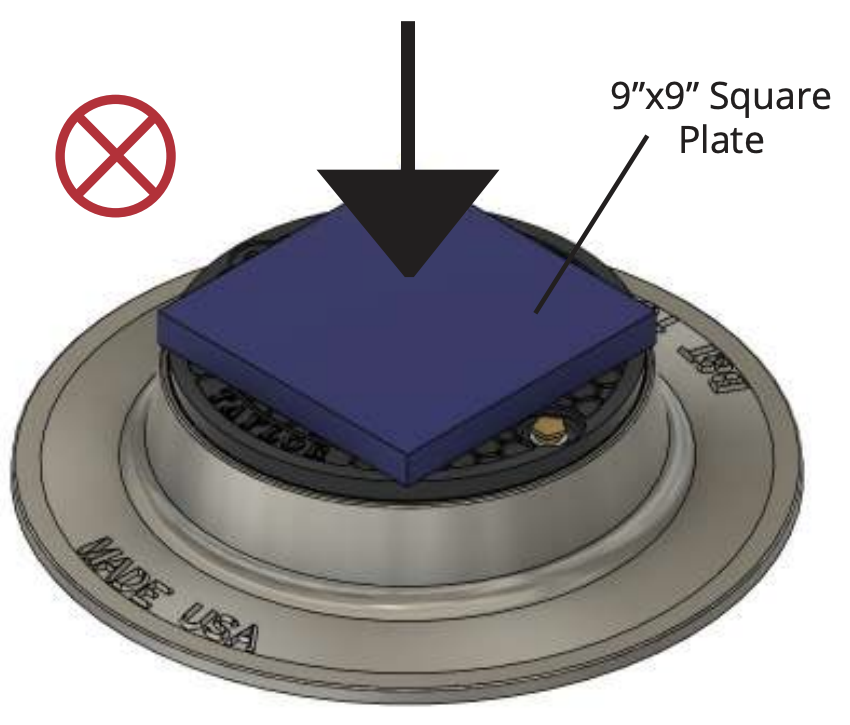

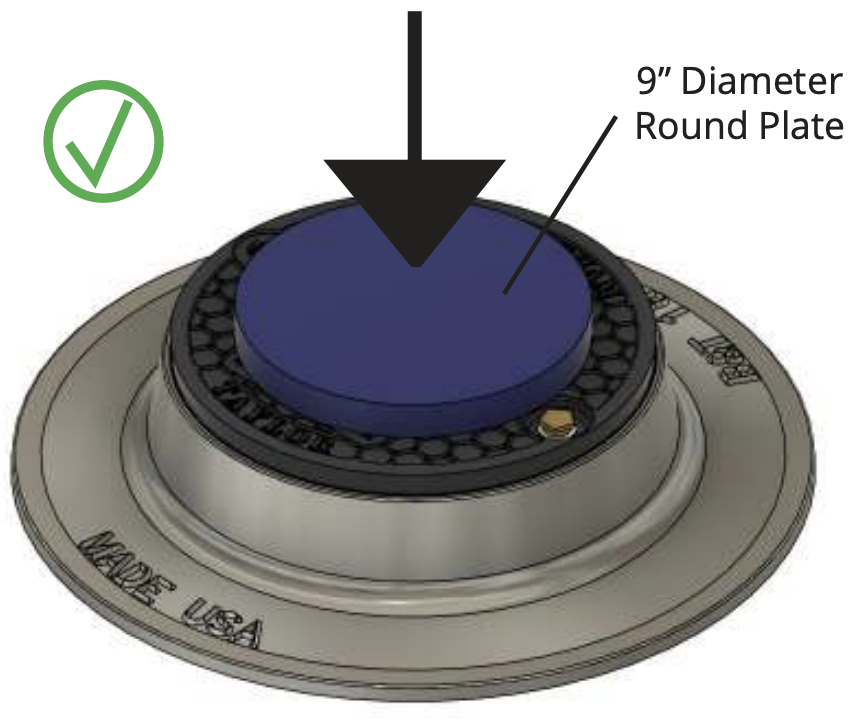

This load is applied evenly over a 9"x9" square area centered on the product.

-

If a 9"x9" footprint would transfer the load to a frame or the ground, the footprint must be smaller than the corresponding frame opening.

-

The load footprint must not exceed 9" in any direction.

-

If the test plate is smaller than 9"x9", the H-20 proof load is calculated by multiplying the plate area by 494 PSI, not to exceed 40,000 lbs.

Key Takeaways from the Test Requirements

-

An H-20 rating means the product must support 40,000 lbs—or the prorated equivalent for products smaller than 9" square.

-

The entire load must be supported by the product itself—not the frame, surrounding structure, or ground.

-

While M-306 applies specifically to cast iron, many in the waterworks industry use the H-20 designation when marketing plastic, composite, or other materials.

|

|

| Lid Not Properly Tested: Load Transferred to Frame |

Lid Properly Tested: Load Fully on the Lid (Not on the Frame) |

Bingham & Taylor’s Composite Plastic Meter Lids, Meter Frames, and Meter Pits

To avoid confusion and ensure full transparency, Bingham & Taylor specifies the exact proof loads used in our testing. We only rate our roadway-installed cast iron products as H-20.

Our plastic meter lids, frames, and pits are designed to meet a robust 20,000 lb proof load. Importantly, our test methods follow AASHTO M-306 standards. We apply loads using plates that clear the supporting frame—no shortcuts or misleading methods.

Some competitors may use load plates larger than the frame opening, which allows the load to be shared with the frame instead of being fully supported by the lid. This may not always be disclosed, so be sure to ask questions. When a plastic lid fails in the field, it can lead to injuries, liability, or worse.

When specifying or approving a plastic product, make sure it meets the demands of your application. If a non-iron product is marketed as H-20, ask for clarification:

-

What test method was used?

-

Was the load fully supported by the product itself?

-

What is the actual proof load?

Lastly, it’s important to note that our plastic lids, frames, and pits are not intended for roadway installation. They are designed to deliver exceptional performance and safety in non-roadway environments.

Bingham & Taylor’s plastic product line is engineered for a 20,000 lb load rating, proudly manufactured in the U.S.A., and available with short lead times.

We are continually expanding our plastic offerings. If you don’t see what you need in our catalog, contact your Regional Sales Manager—they’ll help find the right solution for your application.